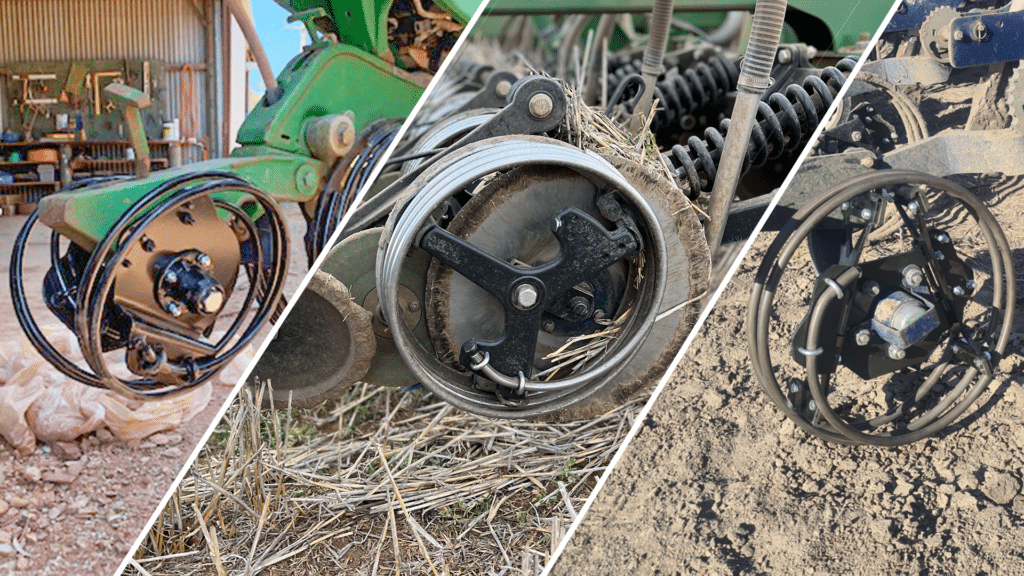

Single Disc Coil Gauge Wheels for Zero Till Farming

Keep planting in wet or sticky conditions with RYAN NT Coil Gauge Wheels.

Single Disc Coil Gauge Wheels for Zero Till Farming

Keep planting in wet or sticky conditions with RYAN NT Coil Gauge Wheels.

Eliminates mud build-up

If mud is ever a problem on your farm, it won’t be anymore!

Plant in any conditions

You won’t need to wait for perfect conditions before heading into the paddock.

Plant on time, any time

Sowing earlier each morning and later each night means you plant on-time, every time.

OUR GUARANTEE:

Your crops will ‘jump' out of the ground due to better seed placement and germination, leading to higher yields and more profit.

Keen to know more? Get in touch with us!

Complete the form below and we’ll call you within 24 hours.

Coil Gauge Wheels: You win with our revolutionary design

You are assured of superior results with the RYAN NT gauge wheel, part of our coil press wheel range for seed drills.

Consider these 3 standout benefits…

1. It’s a simple process to fit our Coil Gauge Wheels to your machine because they are designed to fit most disc planting units.

2. It’s easy to replace worn rubber gauge wheels with Coil Gauge Wheels…and you can still use the existing equipment and parts.

3. The Coil Gauge Wheel has a more open design compared to other solid rubber or inner lipped spoked wheels…which means there will be a noticeable reduction in mud build-up.

You can now get into the paddocks earlier and stay longer

Disc seeders allow farmers to cut through heavy, dry stubbles with minimal soil disturbance BUT are limited in wet conditions due to mud build-up on the discs and gauge wheels. This is no longer a problem with the RYAN NT Coil Gauge Wheels meaning you can get into the paddocks earlier and stay longer.

How is this possible?

👉 The coil wheel system is SELF-CLEANING, so there is no caking or smearing.

👉 Compared to conventional gauge wheels, our coil wheels FLEX allowing dirt to pass through.

👉 The gauge wheels are SPOKED meaning any mud flows right through so you can keep planting in damp or sticky conditions.

👉 Using spokes allows the operator to view and access the disc hub if servicing or maintenance is needed.

Saves time and money

In wet or sticky conditions conventional gauge wheels get caked with mud, so valuable time is lost cleaning. This won’t happen with our coil wheel system.

That means you are saving time and time is money!

Avoid the frustations of delaying planting for a clogged-up disc machine. Coil gauge wheels give disc machines the ability to match a tined rig in the wet.

Productivity and profitability improve when you get your crop in on time. The Coil Gauge Wheels assure you of this, no matter what the conditions.

No problem - leave your stubbles standing

Conventional gauge wheels throw two further problems into the mix:

1. They are wide and when run on previous stubble rows, cause the row unit to ‘bounce’ leading to inconsistent seed placement, poor or uneven germination. This is a major issue if you’re trying to run between winter stubble rows with a single disc opener machine.

👉 Not so with the RYAN NT Coil Gauge Wheels with a deliberately narrow design.

2. They are usually made of urethane or rubber which makes them prone to knocking over standing stubble.

👉 The coils of the gauge wheel substantially reduce this problem because the stubble passes through… adding to the benefits from keeping stubbles standing while still maintaining excellent depth control.

Narrow Gauge Wheels + Spring Coil = Smoother ride, resulting in...

👉 A cushioning effect when planting.

👉 Better seed placement.

👉 When wheels drop into soil depressions you achieve more consistency and precision seeding depth.

👉 Old wheels tracks won’t interfere with depth control and seed placement as they will with the conventional wide gauge wheels.

USA, European, and Australian farmers using the wheels have witnessed remarkable results with corn and cereals on their farms. The team at Ryan Farming Machinery has revolutionised precision seeder and planter gauge wheels, furthermore, taking broadacre farming into the future.

| FEATURES | BENEFITS |

| 3 Compression Spring Coils | Natural flex of the spring coil allows the wheel to self-clean.

Keeps the dry soil away from the seed trench.

No more plugging or blocking.

Rides smoother for better seed placement and germination. |

| Spring Steel | Overcomes replacing rubber tyres. |

| Spoked Design | Easily allows mud to clear from the inside of the wheel. |

| Waterpump 5023 Bearing | Reduced downtime for maintenance. |

| Provision for adjustment with spacers | Adjust gap between disc and gauge wheel for different disc seeder row units and wear. |

| Wheel OD: | 16” (406mm) |

| Width: | 4.5″ (114mm) |

| Coil Thickness: | 0.55” (14mm) spring wire |

| Coil Material: | Spring Metal |

| Rim Material: | Cast Steel |

| Weight: | 12kg or 25.5lb |

| Models for: |

|

RYAN NT Coil Gauge Wheels vs rubber wheels in muddy conditions…

What our farmers have to say

“We have a John Deere 1890 single disc planter and needed to fix the mud and trash buildup. The RYAN NT Coil Gauge Wheel solved this for us…”

– Brad Jenkinson of Warracknabeal (VIC)

Commonly asked questions from our farmers

No, they don't. The patented design allows the coil wheels to shed mud with ease.