Retrofit Double Discs for Zero Till Farming

Dramatically improve productivity with RYAN NT Double Discs.

Retrofit Double Discs for Zero Till Farming

Dramatically improve productivity with RYAN NT Double Discs.

Eliminate machine blockages

Front seeding boot design and scraper stop blockages to give perfect seed placement.

Protects soil structure

Good soil means good yields and profitability, crucial to long-term farming success.

Plant early & dry

Get your planting done early and on time so your crop doesn't miss much-needed moisture.

OUR GUARANTEE:

Your crops will ‘jump' out of the ground due to better seed placement and germination, leading to higher yields and more profit.

Keen to know more? Get in touch with us!

Complete the form below and we’ll call you within 24 hours.

Retrofit RYAN NT Double Discs for exceptional Zero-Till Farming results

If you’re considering upgrading your tine machine, the RYAN NT (formerly RFM NT) Retrofit Double Discs are the perfect option.

Our discs are an alternative to buying a new machine, saving heaps of money in the process! And the good news, RYAN NT Double Discs work on just about any machine manufactured in the last 30 years!

Discs are now an integral and preferred part of the best cropping programs. These, coupled with changing cultivation practices, no-till equipment, heavier bars, interrow sowing and reduced livestock trampling all contribute to higher productivity and profitability.

The system includes disc coulters that make light work of stubble and trash in all soil types. This means you can plant early in dry conditions without making a mess; and you won’t get blocked up in the wet.

And farmers find they can plant up to 30% faster than average and are spending a lot less on fuel.

Another big advantage with the RYAN NT Double Disc opener system is soil moisture retention, far more than using a standard tyne point system.

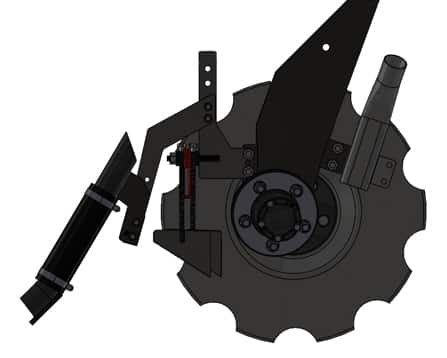

You get superior penetration & cutting with our double discs

Standard disc systems often put the disc coulters side by side causing them to act as a wedge, making it harder to penetrate the soil.

But the RYAN NT Double disc coulters are offset, allowing extra penetration, easier cutting and no hairpinning. This unique system works brilliantly because the lead or driving disc is on the ground, an inch forward of the plain coulter disc.

The plain and serrated coulters mean you get good tilth with enough soil through for chemical incorporation.

The system includes a front seeding boot design, so you avoid blocking and get perfect seed or fertiliser placement directly at the bottom of the trench; also, the spring-loaded scrapers will help alleviate blocking…and the system can double chute.

Outside disc scraper option now available – click here to learn more

Change fast from Tynes to Retrofit Double Discs... and back

Quickly turn your conventional tyne planter into a highly versatile disc planter with the revolutionary RYAN NT multipurpose disc system.

Then just as easily convert it back if conditions require it.

The RYAN NT Retrofit Double Disc system easily attaches to existing tine trip assemblies.

It’s as easy as removing the current shank from the tine trip assembly and replacing it with our matching shank…a simple process involving a couple of bolts or a pin.

The bottom line: You don’t need to buy a new machine, rather convert your existing planting tyne trip for dual purpose with the RYAN NT Double Discs.

For even better results, invest in RYAN NT Press Wheels that work in tandem with the revolutionary Double Discs.

More benefits to improve your productivity and profitability.

PRODUCTIVITY

- You won’t need to buy a new machine, simply retrofit the current one.

- Makes light work of stubble and trash in all soil types.

- Plant early in dry conditions with no mess or blocking up in the wet.

- Less fuel used as planting will be up to 30% faster.

- Offset disc coulters mean no wedge-effect leading to greater penetration.

- No more hair pinning.

- Perfect seed or fertiliser placement with our no-block front seeding boot.

- Spring-loaded scrapers help alleviate blocking.

- The double disc system can double chute.

- Easy conversion back to a conventional machine if required.

- Works in tandem with our unique scrapers to clean discs & stop blocking.

SOIL

- Allows soil to retain more moisture when seeding.

- Better stubble management – higher straw with no blockages.

- No need to burn stubble.

- Plain and serrated coulters work together for improved tilth allowing enough soil through for chemical incorporation.

- Overall, better protection from soil erosion.

Adjustment Spacers

- Adjust the cutting edge between the two discs when wear happens.

| FEATURES | BENEFITS |

| 18″ (450mm) diameter Plain & Serrated Discs |

|

| 15 degree working angle |

|

| Moisture Retention |

|

| Double Bevel Discs |

|

| Recessed design |

|

| 30mm Offset axles |

|

| Heavy duty axle system |

|

| Moisture Retention |

|

| Reduced draft |

|

| Seeding Boot Bracket |

|

| Front seed boot |

|

High-Quality Tapered Bearings

Hub cutaway |

|

| Large range of adapters and shanks |

|

Spring Loaded Mud Scrapers

|

|

| Disc OD: | 18” (450mm) |

| Disc Thickness: | 4mm |

| Material: | Hardened cast steel |

| Disc Weight: | 4kg |

| Single chute or double chute. |

| Rear small seeds boot. |

| Double plain disc combination to reduce throw when pasture seeding. |

| Standard Combination for most broadacre planting applications. |

| Various disc shank models. |

Models for RFM, AFM, Allan Johns, Agrowdrill, Ausplow DBS, Boss, Bourgault, Conservapac, Duncan, Equalizer, Ezee On, Flexicoil, Horwood Bagshaw, Gason, Gyral, Janke, John Shearer, John Deere, Morris, Seed Hawk, Simplicity and Smale.

What our farmers have to say

“We just couldn't be more happy with the result [from switching to RYAN NT Double Discs] in the thick grass country. The germination was fantastic…”

– Sam Clifton of Coonabarabran (NSW)

“I found the RYAN discs online and did a bit of research into them… Since converting to the discs it's been great.”

– Phil Giancono of Donnybrook (WA)

Commonly asked questions from our farmers

Yes, they are greaseable Timkin tapered bearing. There are two bearings to each hub with a rubber seal on the inside. The bearings have the grease nipple positioned between them.

On average, you use 50% less horsepower than you would with a tyne machine. However, many factors influence this requirement, such as soil type, machine configuration, application and what you are trying to achieve.

Deep banding tubes are an option. We have achieved separation with them. It all comes down to soil types and speed.

Very minimal. We recommend that you check disc bearing in the first 100 hours and then grease every 100 hours from thereon.

Yes, they can. It comes down to soil types, speed, and conditions.

The lead disc at the front is always the notched disc.

We regularly plant into hard pastures. The results depend on soil types, speed and conditions.

We recommended starting with 3 spaces on each side. We recommend aiming for a 3-6mm gap at the leading edge of the discs for loam to heavy soils and no more than 1mm for sandy soils. The loam to heavy soils will close the gap between the disc coulters.

Yes, you can. We also stock adapters to suit other tyne models.

Yes, they can. It depends on underframe clearance.